FiberLean at Specialty Papers EU 2023

Advancements in the industrial up-scaling of MFC coating at the paper machine wet-end

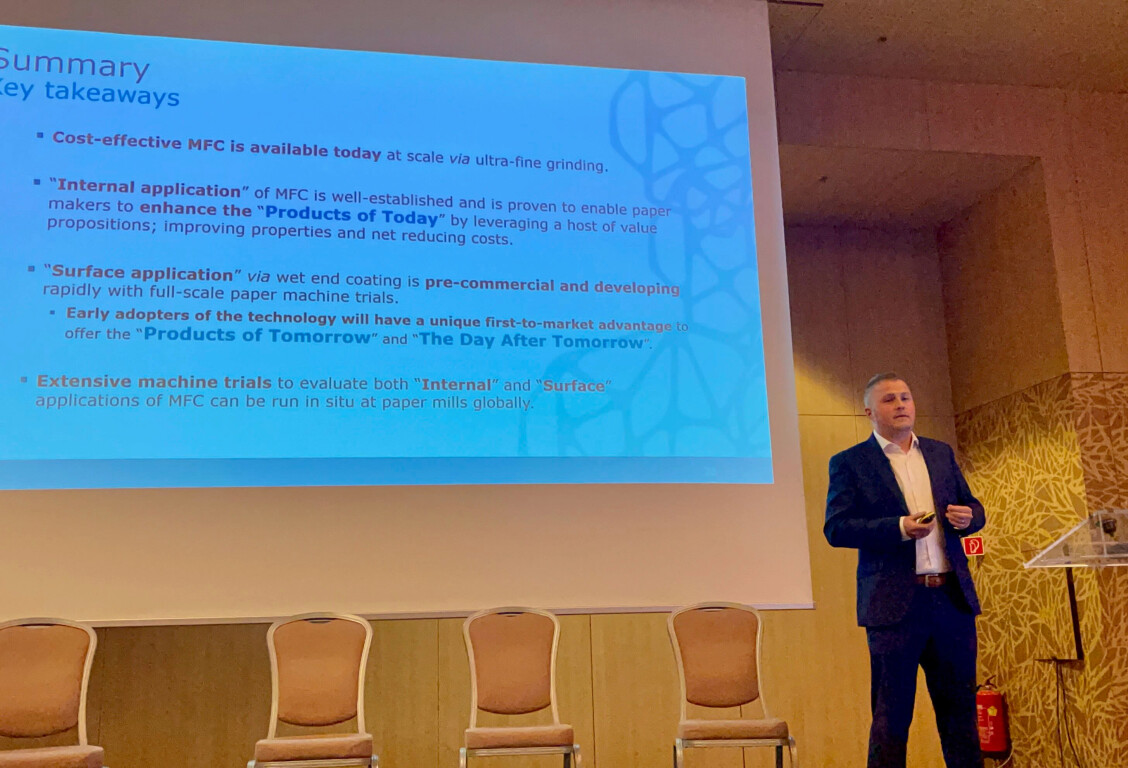

Presented by Tom Larson

Coating of microfibrillated cellulose (MFC) onto the surfaces of fibre-based products shows game-changing potential in the shift towards high-functioning and truly sustainable replacements to petroleum-based materials. When this unique biomaterial is formed into layers and dried onto the sheet surface, the fibrils bind tightly, resulting in very smooth and low porosity films which exhibit barrier properties towards oil and grease, oxygen, aroma, and mineral oils. The layer also serves as an ideal precoat to combine with subsequent coatings in a multi-layer complex to achieve additional barrier properties (e.g., To moisture and water).

The MFC layer can optionally contain minerals, inducing additional functionality to the paper surface. For example, a brown liner can be converted to a white top with excellent printability using a coating of MFC-mineral composite, with MFC being the only binder.

Using the proprietary wet-end coating technique for MFC, FiberLean® on Top, paper makers can achieve these new properties, diversifying their product portfolio with minimal investment costs and avoiding the downtime associated with a machine rebuild. Combining this with onsite MFC production, based on robust ultra-fine grinding modules, ensures reliable supply of raw materials, high quality and cost-effectiveness.

Here we discuss the most recent advances in the exciting up-scaling journey of this revolutionary technology.

To View Tom’s Presentation: View Presentation

Request for more information

To make an enquiry please complete the form below.